Propeller Cap Fin Saving Energy

It is propeller cap fin of large propeller, The material is Ni-Al-Bronze which has very good physical properties and corrosion resistance, mostly apply for marine ship propeller.

This propeller cap fin is used for the large ship over 50000 tons,, high efficiency and saving fuel 2-3% when sailing.

The propeller cap fin is mainly produced by 5 axis CNC machine, all dimensions must be accurate.

The propeller process flow

1, moulding ( wooden pattern for hub, and sand mould for blades),make the upper mould and lower mould for the blades according to the table of offset of the propeller drawing, measure the pitch by the pitch meter in many positions on the blades upper and lower mould, connect the hub mould and blades mould together.

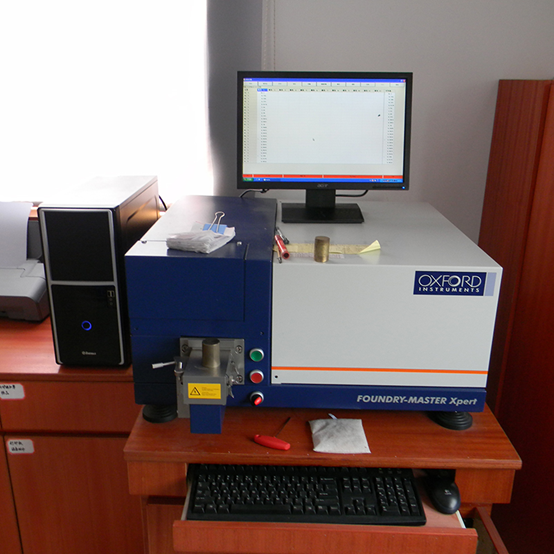

2, Melting the bronze, analyze the chemical composition of the bronze material by spectrum analyzer, make sure the chemical composition is qualified, make the sample bronze rod and test its physical properties,to make sure the physical propeties is qualified.

3, Propeller casting, check the defects of the moulds,and heat the moulds before casting. inspect the casting blank quality, measure the dimension of the casting blank,check the casting blank defects, and make the flaw detection

4, Machining the shaft hole,double ends of the hub, key way of the hub as per the drawing.

5, Polishing the blades surface, and hub surface, according the drawing requirements.

6, finished product inspection, including dimension inspection, balance testing, pitch measuring.